Absorption Costing: Definition, Formula, Calculation, and Example

It is also possible that an entity could generate extra profits simply by manufacturing more products that it does not sell. A manager could falsely authorize excess production to create these extra profits, but it burdens the entity with potentially obsolete inventory, and also requires the investment of working capital in the extra inventory. Absorption costing is an accounting method employed for allocating all direct and indirect production costs to individual products. This methodology is essential because it encompasses all costs incurred in the manufacturing process, thereby enabling manufacturers to set product prices that adequately cover the full scope of production expenses. Both costing methods can be used by management to make manufacturing decisions. For internal accounting purposes, both can also be used to value work in progress and finished inventory.

Impact on Profit

It is possible to use activity-based costing (ABC) to allocate overhead costs for inventory valuation purposes under the absorption costing methodology. However, ABC is a time-consuming and expensive system to implement and maintain, and so is not very cost-effective when all you want to do is allocate costs to be in accordance with GAAP or IFRS. The components of absorption costing include both direct costs and indirect costs.

Absorption Costing vs. Variable Costing: What’s the Difference?

- While this task may seem straightforward for companies specializing in a single or limited range of products, it becomes increasingly complex for firms with a diverse product portfolio.

- The U.S. Securities and Exchange Commission (SEC) and GAAP are primarily concerned with external reporting.

- Absorption costing is a method of product costing that includes fixed manufacturing overhead costs, along with direct material, direct labor, and variable manufacturing costs, in the cost of the product.

- Fixed manufacturing overhead is treated as a product cost in absorption costing and a period cost under variable costing.

- Indirect costs are those costs that cannot be directly traced to a specific product or service.

Under variable costing, the other option for costing, only the variable production costs are considered. On the downside, things can get a little tricky when it comes to making an exact calculation of absorbed costs, and knowing how much of them to include. If all of the variables are not considered carefully (including depreciation, administrative expenses, and yearly fluctuations in your expenses), it can give you misleading results. Activity-Based Costing (ABC) offers a more detailed and nuanced approach by assigning costs to specific activities involved in production.

Variable Costing

For manufacturers seeking to comprehensively understand their profitability, accurately assigning production costs to individual products is crucial. While this task may seem straightforward for companies specializing in a single or limited range of products, it becomes increasingly complex for firms with a diverse product portfolio. These companies must accurately distribute shared overhead costs—like labor, electricity, and assembly-line equipment—across their multiple product lines. In such scenarios, absorption costing serves as the go-to accounting methodology for calculating the complete cost of producing each unit of a product.

- The fundamental distinction between the two lies in the treatment of fixed manufacturing overhead.

- Remember, total variable costs change proportionately with changes in total activity, while fixed costs do not change as activity levels change.

- This content is for general information purposes only, and should not be used as a substitute for consultation with professional advisors.

- Let us understand the concept of absorption costing equation with the help of some suitable examples.

- Absorbed cost allocations for one product produced may be greater or lesser than another.

Absorption Costing Process

Absorption costing can help managers identify areas where costs can be reduced and improve overall efficiency. Another advantage of absorption costing is that financial institutions and investors generally accept it. This makes it easier to obtain financing and raises confidence in the financial statements. This is especially true when compared to other costing methods, such as variable costing.

The three types of absorption costing are job order costing, activity-based costing, and process costing. It can be, especially for management decision-making concerning break-even analysis to derive the number of product units needed to be sold to reach profitability. The key costs assigned to products under an absorption costing system are noted below. Direct labor costs are the wages and benefits paid to employees who are directly involved in the production of a product.

Just-In-Time: History, Objective, Productions, and Purchasing

- Absorption costing incorporates all these costs into the inventory valuation, although it excludes other business expenditures like administrative and sales expenses.

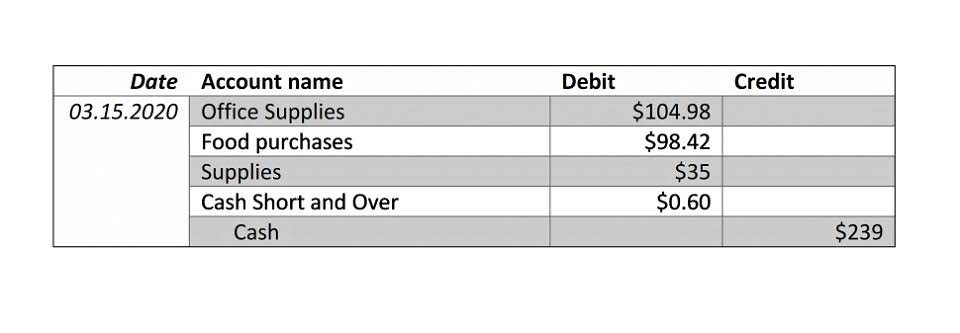

- The following is the step-by-step calculation and explanation of absorbed overhead in applying to Absorption Costing.

- Absorption vs. variable costing will only be a factor for companies that expense costs of goods sold (COGS) on their income statement.

- Absorption costing is a method of costing that includes all manufacturing costs, both fixed and variable, in the cost of a product.

- Absorption costing is mainly used for external financial reporting, income tax computation, and inventory valuation.

- These materials can be easily traced to a specific product, such as raw materials and components.

- Variable costing offers a more direct approach to analyzing costs that vary with production, making it a useful tool for specific types of analysis where absorption costing falls short.